Are you curious about the difference between insert molding and overmolding? Well, let me break it down for you in a simple and informative way!

Click to find more about what is the difference between insert molding and overmolding.

The Distinction: Insert Molding vs. Overmolding

Insert molding involves placing pre-formed components or inserts into a mold cavity before injecting molten material around them. This process creates a strong bond between the insert and the surrounding material, resulting in enhanced structural integrity.

In contrast, overmolding covers an existing component with additional layers of different materials to provide added functionality or aesthetics. It typically involves using two or more materials during the injection molding process to create a composite product.

JVTECH: A Leader in Injection Molding

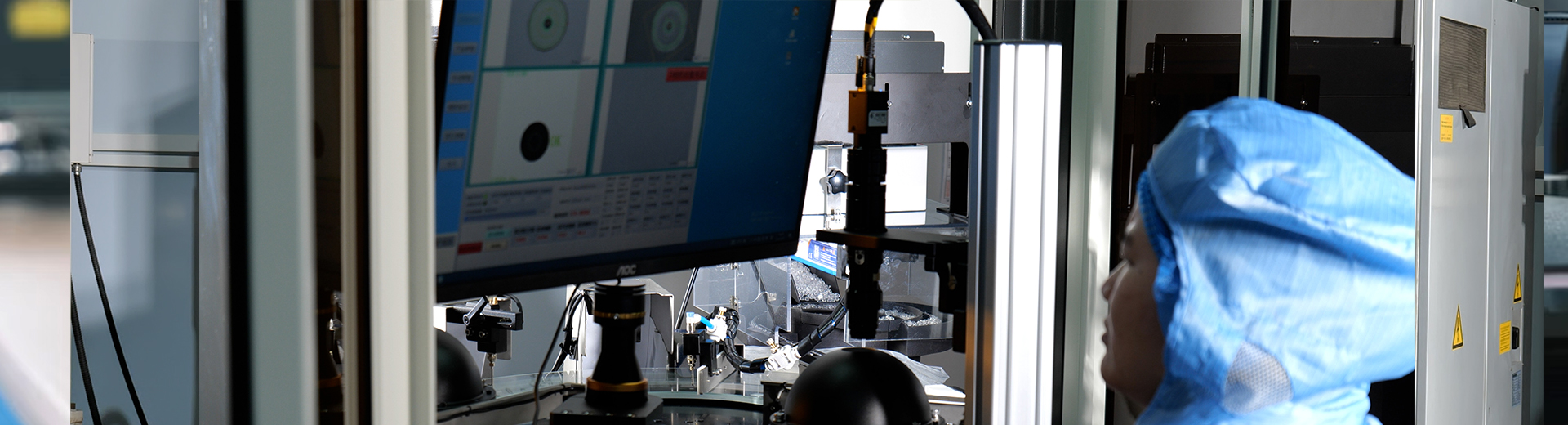

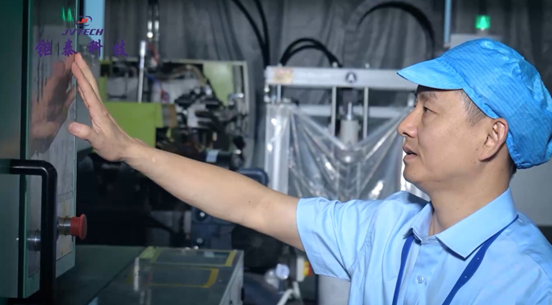

If you’re looking for expert solutions in insert molding and overmolding, JVTECH is your go-to company! With years of experience in precision injection molding techniques, they specialize in producing high-quality products that meet customer specifications.

JVTECH’s state-of-the-art facilities are equipped with advanced machinery capable of handling complex projects. Their team of skilled engineers ensures precise execution throughout every step of the manufacturing process.

The Advantages of Medical Grade LSR

One popular application for both insert molding and overmolding is medical devices. In this field, medical grade Liquid Silicone Rubber (LSR) plays a crucial role due to its exceptional properties.

medical grade lsr offers excellent biocompatibility, making it safe for use within the human body without causing adverse reactions. Its high thermal stability allows sterilization through various methods such as autoclaving or gamma radiation without affecting its performance.

Furthermore, LSR provides superior flexibility, durability, and resistance to chemicals and extreme temperatures. These qualities make it an ideal material for producing medical devices that require precision, reliability, and long-term functionality.

In Conclusion

So there you have it! The difference between insert molding and overmolding lies in the process of incorporating additional materials into a mold. JVTECH is a leading company specializing in these techniques, ensuring top-notch quality products. And when it comes to medical applications, the use of medical grade LSR offers numerous advantages.

Whether you need insert molding or overmolding services or are interested in utilizing medical grade LSR for your next project, understanding these concepts will help you make informed decisions about your manufacturing needs!