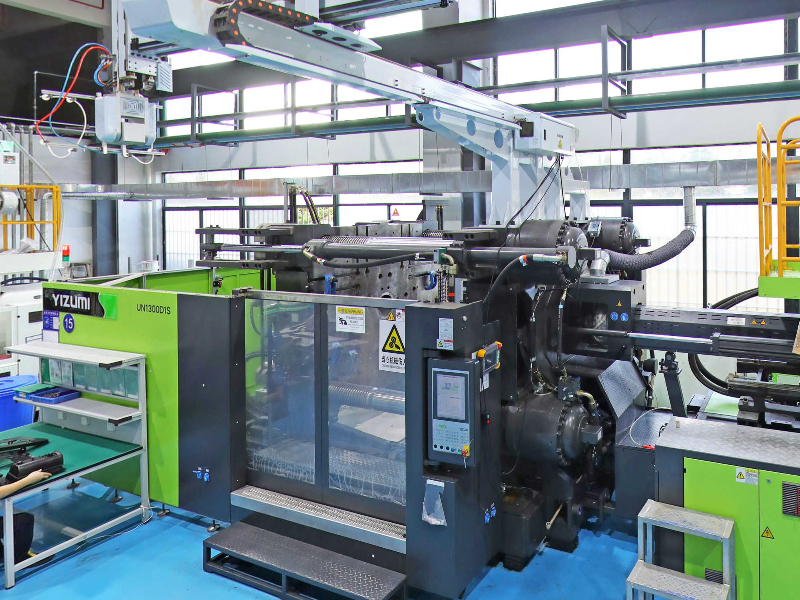

Exploring Prototype CNC Machining

Prototype CNC machining is revolutionizing the manufacturing landscape, providing unmatched precision and efficiency in product development. By utilizing cutting-edge technology, this method allows designers and engineers to create prototypes that closely resemble the final product in both functionality and appearance. The allure of prototype CNC machining lies not just in its accuracy but also in its ability to drastically reduce the time and costs associated with traditional manufacturing methods. Imagine designing your product in a CAD program and having a tangible prototype in just a matter of days; this is the promise that prototype CNC machining delivers. Whether you are an independent inventor or part of a larger organization, investing in this technology can enhance your innovation capabilities, bringing your ideas from concept to reality quickly and effectively. For those looking to implement this technology, it is essential to partner with experienced providers for optimal results. Explore more about how prototype CNC machining can transform your design process.

The Power of CNC Rapid Prototyping

Embracing cnc rapid prototyping can drastically improve your product development cycle. This method allows for rapid iterations, enabling designers to test and refine their ideas efficiently. In a world where time-to-market can make or break a product, CNC rapid prototyping serves as an invaluable tool. It empowers teams to create multiple prototype versions in a matter of hours, allowing for quicker feedback and adjustments based on testing and user input. Take, for instance, a tech startup working on a new gadget; by employing CNC rapid prototyping, they can swiftly switch designs and functionalities based on consumer trends and needs, ultimately leading to a product that resonates well with its target audience. This agility not only enhances product quality but also fosters innovation and collaboration among team members, breaking down silos and encouraging a more integrated approach to product development.

Enhancing Creativity with CNC Rapid Prototyping

The landscape of design is rapidly evolving, and cnc rapid prototyping is at the forefront of this change. This technology allows creators to flesh out their ideas, turning visions into physical forms almost instantaneously. The capability to produce prototypes at such a speed enables designers to push their creative boundaries, experiment with complex geometries, and explore materials that were previously thought inaccessible. For a small business owner, this could mean testing innovative packaging designs that not only protect the product but also attract customers on the shelves. The immediacy of CNC rapid prototyping means that design missteps can be identified early in the process, saving valuable resources and ensuring that the final product meets consumer expectations. By integrating CNC rapid prototyping into the design workflow, businesses can harness their creativity more effectively, ultimately yielding higher-quality outcomes and enhanced customer satisfaction.

Conclusion: Why APT-Mold Should Be Your Go-To Partner

In summary, whether you are looking to shorten your product development cycle or enhance the level of creativity within your design team, adopting prototype CNC machining and cnc rapid prototyping can yield significant benefits. These innovative techniques not only save you time and money but also empower you to bring remarkable products to life more efficiently. As you consider the right partner to help guide you through your journey, look no further than APT-Mold. With their expertise in manufacturing and a dedicated focus on client needs, APT-Mold stands out as a supplier with distinct advantages in the field. Their commitment to quality and efficiency ensures that your prototypes not only meet but exceed expectations. Trust APT-Mold to be the ally you need in your pursuit of innovation and excellence.